Introduction

Bearings are the backbone of robotic systems, enabling seamless motion, reducing energy loss, and ensuring precision in tasks ranging from industrial automation to delicate surgical procedures. As robots advance in complexity and adaptability, the demand for specialized bearings continues to grow.

1. Key Types of Bearings in Robotics

- Deep Groove Ball Bearings: Widely used in robotic joints and motors for handling moderate radial and axial loads with cost-effective simplicity.

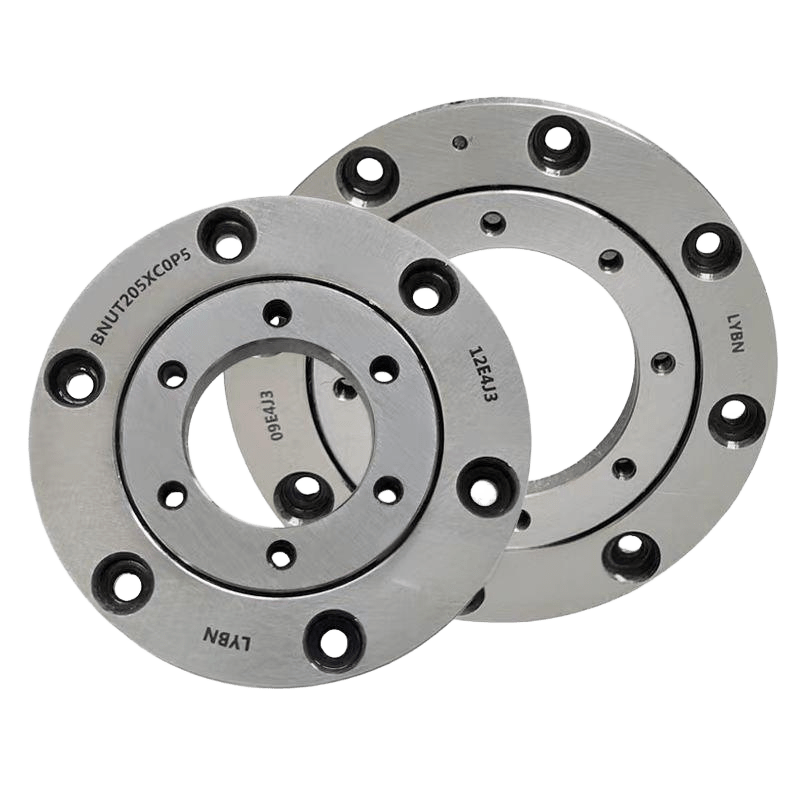

- Crossed Roller Bearings: Essential for high-precision robotic arms and rotary tables, supporting combined radial/axial loads.

- Angular Contact Ball Bearings: Optimized for high-speed axial loads in spindle systems and servo motors.

- Active Magnetic Bearings: Emerging in advanced robotics, these use electromagnetic forces for contactless operation, reducing wear and enabling dynamic adjustments.

2. Critical Functions & Applications

- Precision Control: Bearings maintain positional accuracy in tasks like surgical robotics and assembly lines.

- Load Distribution: They manage forces in multi-axis systems, such as humanoid joints or collaborative robots (cobots).

- Energy Efficiency: By minimizing friction, bearings extend battery life in autonomous drones and mobile robots.

3. Material & Design Innovations

- Ceramic Hybrid Bearings: Lightweight and thermally stable, ideal for high-speed drones and space robotics.

- AI-Optimized Geometry: Machine learning refines bearing designs for specific loads, noise reduction, and longevity.

- Smart Bearings: Embedded sensors monitor stress and temperature in real time, enabling predictive maintenance.

4. Cutting-Edge Applications

- Medical Robotics: Crossed roller bearings ensure micron-level precision in surgical tools and imaging systems.

- Humanoid Robots: Advanced bearings replicate human biomechanics in joints, enabling lifelike motion.

- Autonomous Systems: Magnetic bearings enhance agility in drones and self-balancing robots.

5. Future Trends

- Sustainability: Recyclable polymers and bio-lubricants align with eco-friendly robotics.

- Customization: Tailored bearings for AI-driven systems, such as adaptive grippers or swarm robots.

- Integration with AI: Bearings will synchronize with real-time data analytics for self-adjusting performance.

Share:

Lightweight Robotic Joint Module: Technical Architecture and Industrial Evolution Core Technological Innovations

Dexterous Robotic Hand: A Game-Changer in Automation