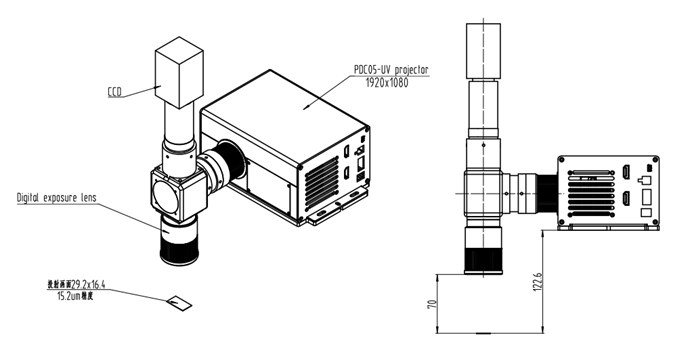

Coaxial Printing Monitoring UV Light Engine

The CPM09 (Coaxial printing monitoring UV light engine) adopts a coaxial optical path design, and the camera collects the image in real time when the UV light engine is digitally exposed. When exposing printing, monitor the clarity and brightness of the image through the camera; Precision manufacturing, biomedicine, advanced electronics and other fields have disruptive potential, especially suitable for small batch, high complexity, multi-material micro-nano device needs.

Product features:

Real-time monitoring and closed-loop control

The integrated CMOS camera captures the light-curing status of the printed layer (e.g., resin shrinkage, bubble defects) in real time. It can be combined with AI algorithms (such as convolutional neural networks) to automatically analyze the image and feedback to adjust parameters (such as exposure time, light intensity, sharpness) to avoid interlayer misalignment or collapse. Application scenario: When printing microfluidic chips, real-time detection of channel deformation and compensation of exposure strategy.

Dynamic light field modulation

Through the synergy of the DMD and the coaxial optical path, grayscale exposure or multifocal light field can be realized, supporting continuous printing of complex gradient structures (such as biomimetic vascular networks). For example, in a single-layer exposure, the local curing depth can be adjusted by a grayscale mask to reduce the need for post-processing.

Compatible with a wide range of magnification lenses

According to the requirements of process parameters, different lenses can be selected to achieve different printing formats, and a single exposure area can reach centimeter level, combined with multi-UV light engine splicing technology to achieve large-area microstructure arrays (such as mass production of flexible electronic circuits).

Application:

Biomedical Engineering

Vascularized tissue scaffolds: Gradient pore structures (e.g., 50-200μm pore size) are printed by grayscale exposure to promote cell migration and nutrient permeation.

Microneedle array: Manufacture of dissolvable microneedles (drug-loaded hydrogel) for painless transdermal drug delivery.

Lab-on-a-chip: Integrates a microfluidic channel with an optical sensor (e.g., fluorescence detection area) for single-cell analysis.

Microelectromechanical Systems (MEMS)

Micro actuator: Microactuator that directly prints piezoelectric/thermally responsive structures (e.g., bionic insect wings with a size of 100 μm).

Flexible electronics: Printing silver nanowire circuits (e.g., wearable strain sensors) on curved surfaces.

Energy & Environment

Micro fuel cell: Manufacture of an integrated structure of microfluidic channel and catalytic electrode to improve reaction efficiency.

Seawater desalination membranes: Printing biomimetic membrane materials with nanoscale pores (e.g., mimicking the gradient structure of mangrove roots).

Research and prototype development

Metamaterial research: Rapid verification of acoustic/electromagnetic metamaterial designs (e.g., negative refractive index structures).

Microreactor: Customized printing of micron-level chemical reaction chamber for catalytic experiments.

Specs:

|

Model |

PMS -2.7 |

PMS-7.6 |

PMS-15.2 |

|

Resolution |

2.7um |

7.6um |

15.2um |

|

Image Size |

5.18mm*2.92mm |

14.59mm*8.21mm |

29.18mm*16.42mm |

|

Distortion |

0.10% |

0.10% |

0.10% |

|

Distance |

21.4mm |

31mm |

70mm |

|

Wavelength |

405nm/385nm |

||

|

DMD |

DLP6500 1920*1080 |

||

|

CMOS Resolution |

4024x3036 |

||

|

Interface |

HDMI USB2.0 USB3.0 |

||

Coaxial Printing Monitoring UV Light Engine

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

FAQs

Please read our FAQs page to find out more.

What transportation method do you use?

All our products are shipped via international express services, such as DHL and FedEx,? completely free of charge

What is DLP 3D printing, and how does it work?

DLP 3D printing is a resin-based additive manufacturing technology that uses light to cure liquid photopolymer layer by layer. It involves projecting digital images onto a vat of liquid resin, where the exposed resin hardens to form each layer of the 3D object.

How does DLP 3D printing differ from other 3D printing technologies?

DLP 3D printing differs from other technologies such as FDM (Fused Deposition Modeling) in its use of light to cure resin, which allows for faster and more precise printing. It also typically offers higher resolution and smoother surface finishes.

Why are UV projectors critical in DLP 3D printing?

UV projectors are critical in DLP 3D printing because they emit the ultraviolet light that cures the resin. The quality, speed, and reliability of the printing process depend heavily on the performance of the UV projector.

What factors should be considered when selecting a UV projector for DLP 3D printing?

When selecting a UV projector, factors to consider include wavelength, resolution, LED lifespan, controller compatibility, and mechanical integration. The ideal projector should match the specific needs and requirements of the DLP 3D printing system.

What are the system requirements for DLP 3D printing?

System requirements for DLP 3D printing include a compatible UV projector, resin vat, build platform, and control system. Specific hardware specifications, such as resolution and interface compatibility, should also be considered.

How do I connect and configure a DLP 3D printing system?

Connecting and configuring a DLP 3D printing system typically involves connecting the UV projector to a PC via USB, launching the manufacturer's proprietary configuration software, and setting up the printer parameters, such as layer thickness and exposure time.

What is "pixelation" in DLP 3D printed models, and how can it be addressed?

Pixelation" refers to the appearance of tiny square or grid-like patterns on the surface of DLP 3D printed models. It can be addressed by increasing the resolution of the UV projector, adjusting the light curing parameters, or optimizing the print path.

What role do TIR prisms play in DLP 3D printing, and why are they important?

TIR (Total Internal Reflection) prisms play a critical role in DLP 3D printing by precisely redirecting light from the micro-mirror arrays to the projection optics. They maintain polarization and ensure that the light is evenly distributed across the resin vat, which is essential for high-quality printing.

What languages and currencies are supported on

The website supports multiple languages, including English, Simplified Chinese, Arabic, Korean, German, and Japanese. It also offers a variety of currency options, such as USD, EUR, AUD, and more, to cater to international visitors.

How can I stay updated with new collections and exclusive offers

To stay updated with new collections and exclusive offers, you can subscribe to the website's newsletter by providing your email address. This will allow you to receive notifications about the latest products, promotions, and news directly to your inbox.