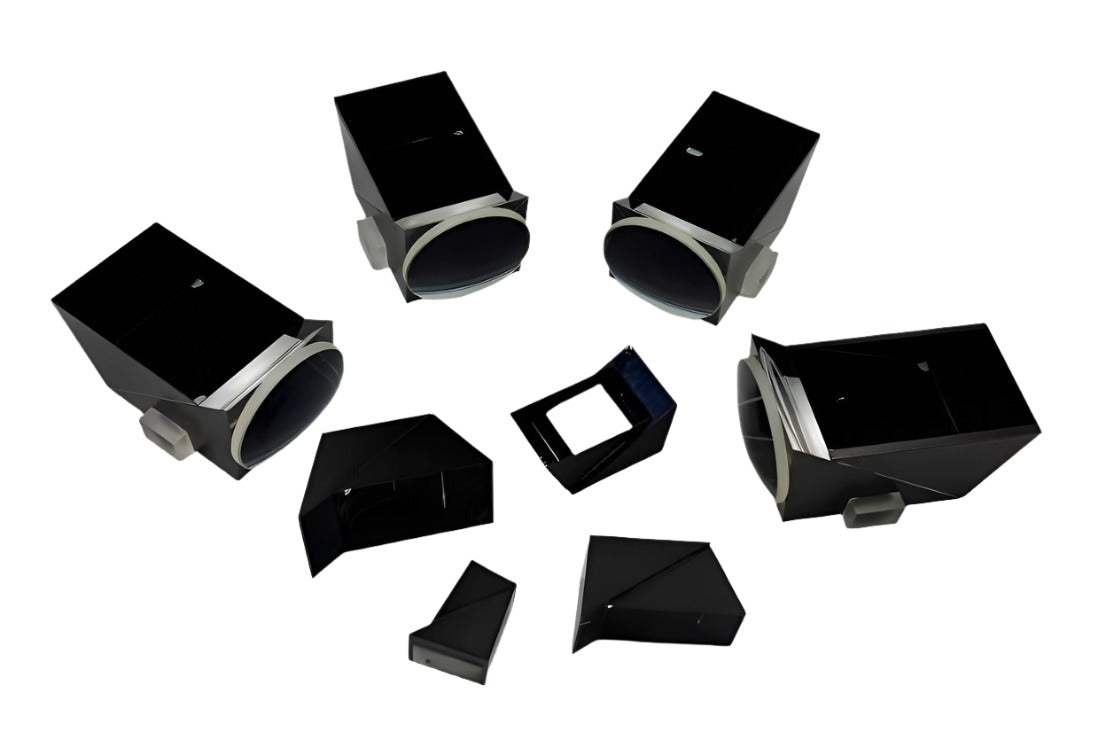

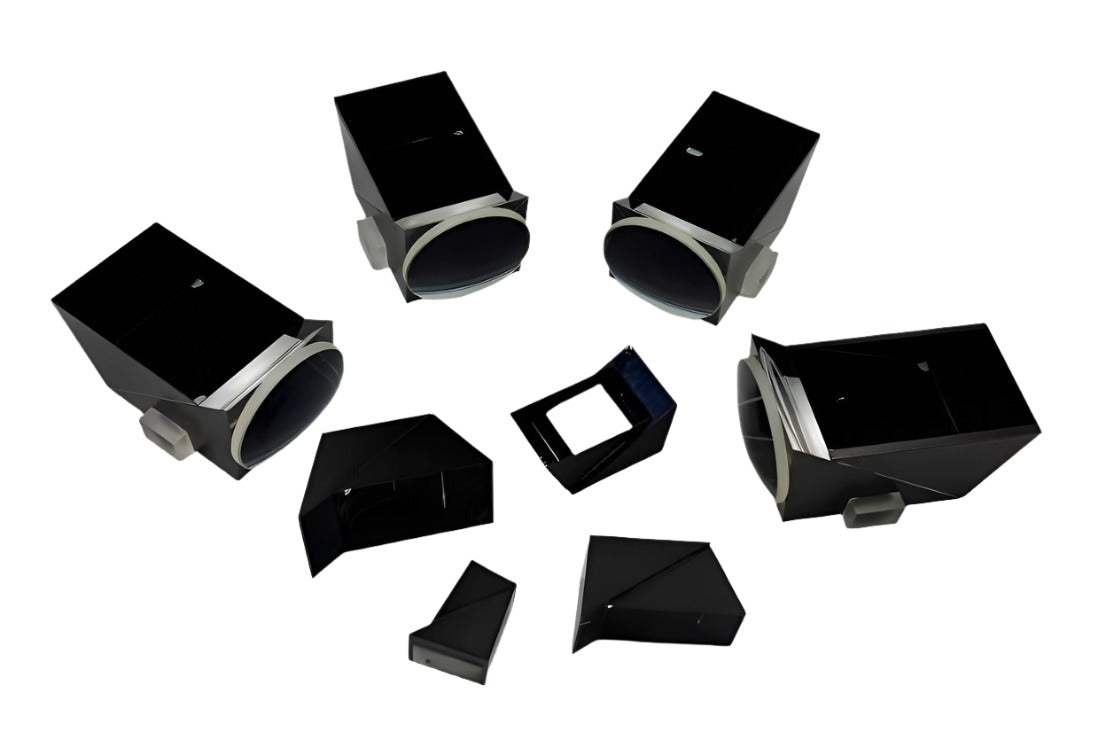

TIR prisms for the DLP9000 Projection System,MOQ 10pcs lead time 50days

Attention:For this special DLP9000 TIR prisms, MOQ is 10pcs now ,Lead time is 50days. UV 405nm DLP6500 TIR prisms have stock now.

0.9 inch Total Internal Reflection (TIR) prisms for the TI DMD DLP9000 Projection System

Our custom TIR prisms are manufactured to the highest quality standards, ensuring top-notch quality and reliability.

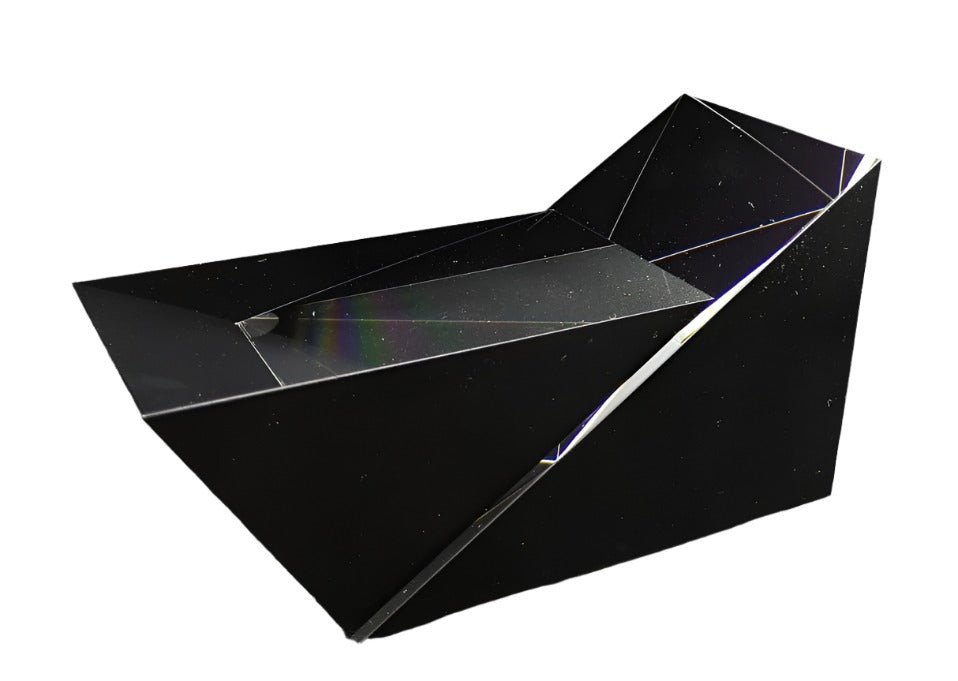

These 0.9 inch Total Internal Reflection (TIR) prisms for TI DMD DLP9000 Projection System accurately direct incident light to a DMD chip, ensuring a crisper image. These TIR prisms are the ideal choice for use in any TI-DLP 9000 projector system. They are built from high-end optical components and offer excellent value for money.

- The finest quality: When you choose to buy 0.9 inch Total Internal Reflection (TIR) prisms from us, you can be confident that you are getting the finest quality products available in the market today.

- Achieve crisp and clearer projections: The Total Internal Reflection (TIR) prisms add a little extra light power to the image, making sharper and clearer projections.

- Eco-Friendly Manufacturing Process: We care for the environment and we want to make a positive impact on the planet as we grow. Expect that these TIR Prisms for your DLP6500 projector system are manufactured under the appropriate environmental protection standards.

- Wide variety: SICUBE's high precision prisms include TIR prisms, RTIR prisms for DLP light engines, PBS prisms, combination prisms, biometric prisms, AR prisms, and more.

More Details:

- Full process machining and testing capability

- Customized production, timely delivery

- Processing capacity: angle accuracy: 5"; surface accuracy: within 1/10 λ; dimension accuracy: + 0.02mm

- Green production, environmental protection

- SICUBE can produce various sizes of TIR and RTIR prisms for DLP projection optical systems, suitable for 0.2, 0.3, 0.45, 0.47, 0.65, 0.95-inch DMD chips. In addition to providing conventional visible TIR/RTIR prisms, SICUBE provides both 365 nm-405 nm and 750 nm working band TIR prisms for 3D printing and sweeping requirements.

TIR prisms for the DLP9000 Projection System,MOQ 10pcs lead time 50days

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

FAQs

Please read our FAQs page to find out more.

What transportation method do you use?

All our products are shipped via international express services, such as DHL and FedEx,? completely free of charge

What is DLP 3D printing, and how does it work?

DLP 3D printing is a resin-based additive manufacturing technology that uses light to cure liquid photopolymer layer by layer. It involves projecting digital images onto a vat of liquid resin, where the exposed resin hardens to form each layer of the 3D object.

How does DLP 3D printing differ from other 3D printing technologies?

DLP 3D printing differs from other technologies such as FDM (Fused Deposition Modeling) in its use of light to cure resin, which allows for faster and more precise printing. It also typically offers higher resolution and smoother surface finishes.

Why are UV projectors critical in DLP 3D printing?

UV projectors are critical in DLP 3D printing because they emit the ultraviolet light that cures the resin. The quality, speed, and reliability of the printing process depend heavily on the performance of the UV projector.

What factors should be considered when selecting a UV projector for DLP 3D printing?

When selecting a UV projector, factors to consider include wavelength, resolution, LED lifespan, controller compatibility, and mechanical integration. The ideal projector should match the specific needs and requirements of the DLP 3D printing system.

What are the system requirements for DLP 3D printing?

System requirements for DLP 3D printing include a compatible UV projector, resin vat, build platform, and control system. Specific hardware specifications, such as resolution and interface compatibility, should also be considered.

How do I connect and configure a DLP 3D printing system?

Connecting and configuring a DLP 3D printing system typically involves connecting the UV projector to a PC via USB, launching the manufacturer's proprietary configuration software, and setting up the printer parameters, such as layer thickness and exposure time.

What is "pixelation" in DLP 3D printed models, and how can it be addressed?

Pixelation" refers to the appearance of tiny square or grid-like patterns on the surface of DLP 3D printed models. It can be addressed by increasing the resolution of the UV projector, adjusting the light curing parameters, or optimizing the print path.

What role do TIR prisms play in DLP 3D printing, and why are they important?

TIR (Total Internal Reflection) prisms play a critical role in DLP 3D printing by precisely redirecting light from the micro-mirror arrays to the projection optics. They maintain polarization and ensure that the light is evenly distributed across the resin vat, which is essential for high-quality printing.

What languages and currencies are supported on

The website supports multiple languages, including English, Simplified Chinese, Arabic, Korean, German, and Japanese. It also offers a variety of currency options, such as USD, EUR, AUD, and more, to cater to international visitors.

How can I stay updated with new collections and exclusive offers

To stay updated with new collections and exclusive offers, you can subscribe to the website's newsletter by providing your email address. This will allow you to receive notifications about the latest products, promotions, and news directly to your inbox.